by steve yang | Mar 7, 2025 | injection molding

Prototype die casting is a crucial manufacturing process that enables businesses to create high-quality metal prototypes with precision and efficiency. It is widely used across industries such as automotive, aerospace, electronics, and consumer goods to test and...

by steve yang | Feb 18, 2025 | injection molding

Metals play a crucial role in industrial manufacturing, automotive engineering, aerospace applications, and consumer products. Among the most commonly used lightweight metals are magnesium, aluminium, and zinc, each possessing unique properties that make them suitable...

by steve yang | Feb 18, 2025 | injection molding

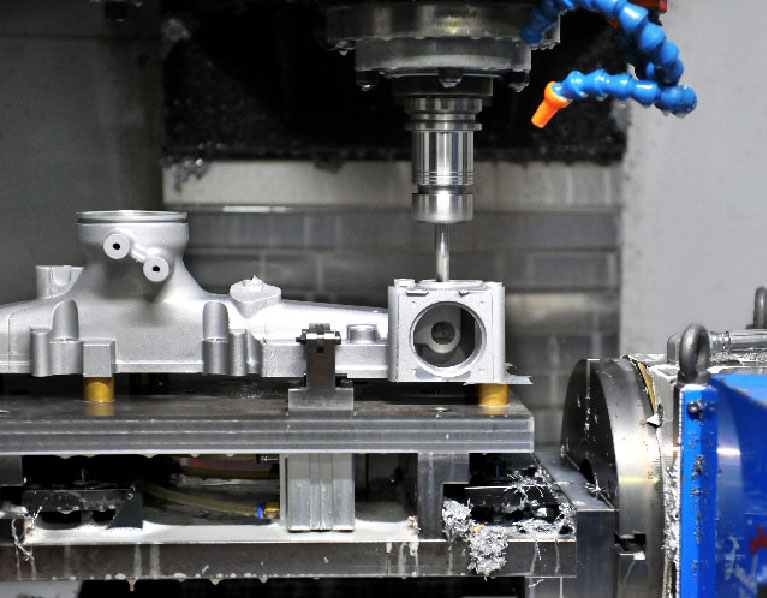

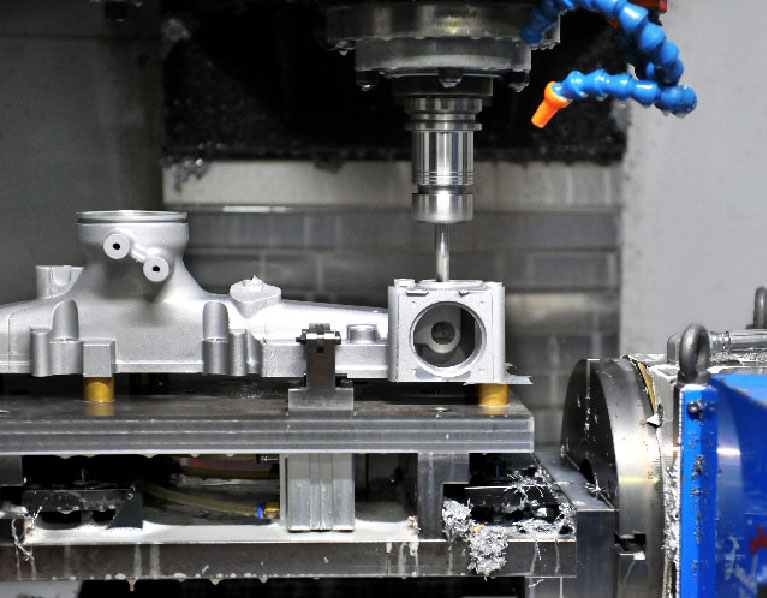

CNC machining has become a crucial part of modern manufacturing, enabling the production of high-precision parts for various industries. As technology advances, China has emerged as a global leader in CNC machining, offering high-quality services at competitive...

by steve yang | Feb 11, 2025 | injection molding

Michigan is a hub for plastic injection molding companies, driven by its deep ties to manufacturing and engineering. Known as the epicenter of the automotive industry, Michigan’s industrial landscape has expanded over the years to include a wide range of plastic...

by steve yang | Feb 7, 2025 | blow injectioin molding, injection molding

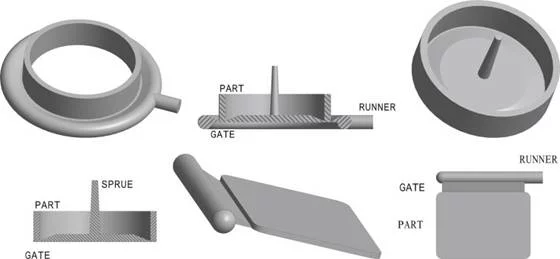

In the injection molding process, the injection molding gate is a crucial feature that determines how molten material enters the mold cavity. The gate serves as the entry point for the plastic to flow into the mold, and its design and placement directly influence the...

by steve yang | Jan 31, 2025 | injection molding

Plastic injection molding is a widely used manufacturing process for producing strong and precise plastic components in various industries. However, in many applications, plastic alone may not provide the necessary durability, thread strength, or resistance required...